If your business does a significant amount of metal cutting, you may start wondering whether it's best to invest in the equipment yourself. Fiber lasers, along with plasma cutters, can be an option. But how do you know whether a fiber laser is right for your company?

Is fiber laser right for your business?

Fiber laser technology is accurate, fast, and high in quality. But it's also more expensive than many other options. There are a few things you need to consider before you decide on a fiber laser.

Are you currently outsourcing your metal cutting?

Take a look at how much metal cutting you're doing and what the cost of outsourcing that labor is. Consider that a fiber laser will generally last a business around 100,000 hours. Now compare the two costs. Are you saving money by outsourcing your metal cutting? Or would having a fiber laser ultimately cost you less?

What kind of financing model would you be looking at?

Consider also that a fiber laser is also an asset — and a depreciable asset at that. If you could go through your bank to finance a fiber laser at less than your monthly expenditure for outsourcing your metal cutting, it's possible that purchasing a laser could actually improve your cash flow. Not only will you be able to write off depreciation on your taxes as an expense, but you'll also have an asset that can be potentially liquidated.

Do you need more control over your system?

Do you find yourself struggling to get the detail or quality from an outsourced laser cutting team? Is it possible that you could improve the quality of your product by having your own laser cutter? Have you missed deadlines or run close to them because your outsourced team couldn't deliver on time? Having your own fiber laser means you don't need to worry about working with a third party to deliver your own goods.

Do you already have a system?

Do you have a metal cutting system that is no longer giving you the performance that you need? You might have a laser cutter that just isn't providing you with the fidelity or the tolerances that you desire. It may be time to upgrade to a fiber laser; you can run samples and see the difference.

Are you trying to prototype?

Doing your prototyping in-house can not only save you time and money but ultimately improve the end quality of the product, as you'll have more control over your design and development process. If you're prototyping products currently, a fiber laser might be the ideal solution.

Not every business needs to purchase a fiber laser. Some organizations will be able to happily continue to outsource their metal cutting. But for companies that do a lot of meta cutting or that want complete control over their designs and their development, purchasing a fiber laser may be the right choice.

Fiber laser equipment is an investment. And it's a type of tangible asset. There are many ways to secure financing for a fiber laser, should you decide that it is the right choice for your business model. If you have questions, contact us today.

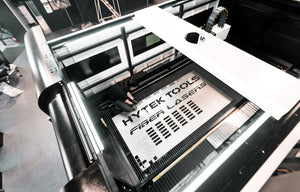

Watch Matthew and his crew tune in a 6kw Fiber Laser with Exchange table, and deliver it to it's new home at the end of the video:

Matthew Voss from Hytek Tools

SHOP for BUY FIBER LASER IPG - MAX