Fiber Laser for Metal Fabrication

What Is Fiber Laser Cutting?

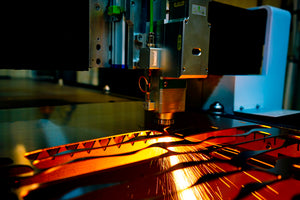

Fiber laser cutting, simply called “laser cutting” or just “laser” is a type of CNC machining. Light goes through fiber optic cables and gets amplified along the way. It then gets straightened and focused through a lens.

The lens is positioned directly above a tray where we place material, commonly sheet metal. The lens is positioned on a head which is affixed to a gantry. The head will move in the XY plane and Z direction, performing cuts on the metal underneath.

Comparing Laser, Plasma, and Waterjet Cutting

Laser cutting can be compared to plasma and waterjet cutting. In fact, all three machines look very similar from a distance, and they’re used in about the same applications: for cutting materials quickly. They’re especially useful in making sheet metal pieces with complex geometries or multiple features.

Let’s look at some specific categories and how they compare.

Upfront Cost

Laser machines are the most expensive out of these three. Plasma cutters are the least expensive and waterjet cutters are in-between the two.

Operating Cost

Fiber Laser runs about 40% less on consumables than plasma cutting. Hytek Tools stock the obscure consumables like nozzles and lenses in bulk, and passes the savings to our clientele.

Cut Quality

The final quality of the cut is a huge deal for most manufacturing facilities. This refers to how square the final cuts are, and if there are unnecessary rounded areas.

Laser and waterjet cutters are neck-and-neck when it comes to quality. They both achieve superior cut qualities and much more squared cuts. Plasma cuts always come with some level of roundness on all of their cuts.

Speed of Cut

Laser cutting offers the fastest speeds. Since there are no mirrors, pressurization, or heating up required, the head can immediately cut and move a lot faster across materials.

Waterjet cutters are the slowest since they’re reliant on how slowly pressurized water can cut through metal.

Dynamic Thickness Cutting

A benefit that laser cutters have over the other two is the ability to cut through materials of different thicknesses. Waterjet and plasma cutters have to be set for a single material thickness before the cut starts.

With laser cutting, you can cut multiple materials of multiple thicknesses with the same program setup.

Is Fiber Laser Cutting Viable for Mass Production?

CNC machines are often the go-to method of mass-producing metallic parts (whereas molding is used for plastic mass-produced parts).

In this case, fiber laser cutters are viable in mass production. They create multiple parts:

- Reliability (fiber source 100,000 hours of service)

- Repeatability

- Speed

- little to no human interaction

- incredible accuracy

- different thicknesses with a single program

Get the Best Fiber Laser Results

If you want the best results, you need a company that uses high-quality fiber laser sources like IPG Photonics, and has tons of experience delivering industrial machinery. You’ll find that at Hytek Tools.

Check the Fiber Laser Machine Shop Here

Watch Matthew and his crew tune in a 6kw Fiber Laser with exchange table, and deliver it to it's new home at the end of the video:

6kw Fiber Laser Tuning